High Voltage Contactors

Contactors use a low power input to switch high power circuits. You can hear them mechanically switching (a "clack" sound) as you change throttle modes between off/forward/reverse. All of the high voltage contactors fail safe to "off". An overview diagram showing how the throttle, motor controller, and contactors integrate can be found here.

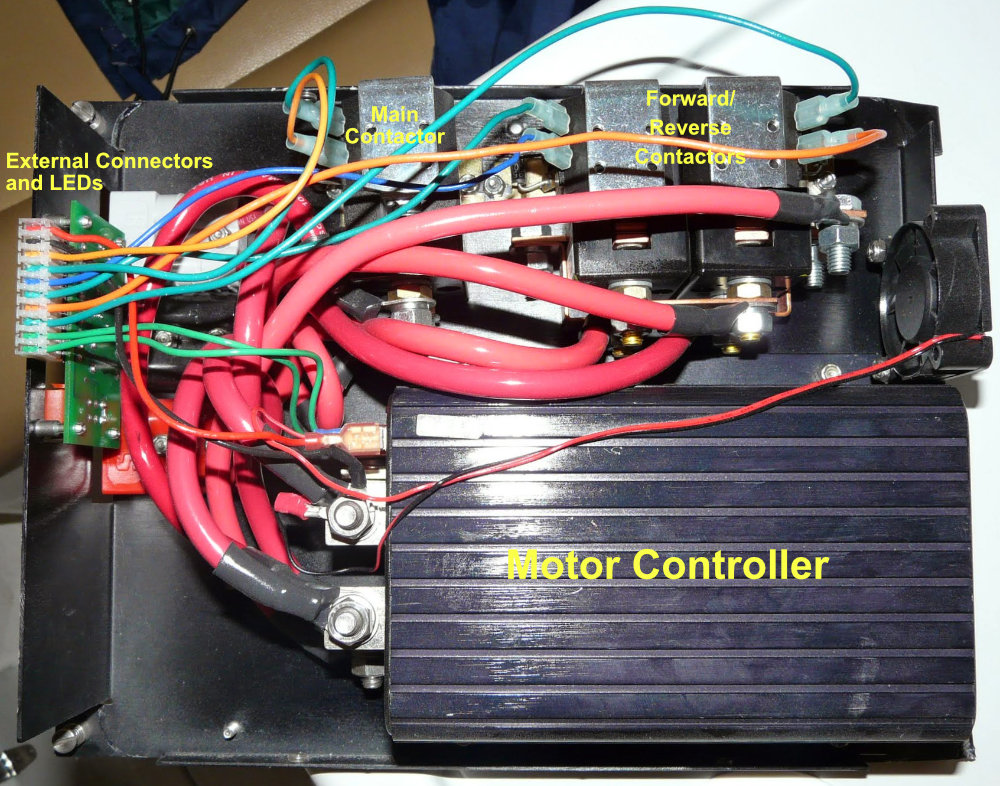

Our contactors are Ametek JAA4602AB00 for the main contactor and Ametek JAM4603AA00 for the forward/reverse contactors. These are rated for 48VDC. You should have functionally equivalent contactors that may have different specifications depending upon your boat's configuration.

The main contactor is a N.O. SPST switch that provides high voltage DC to the motor controller.

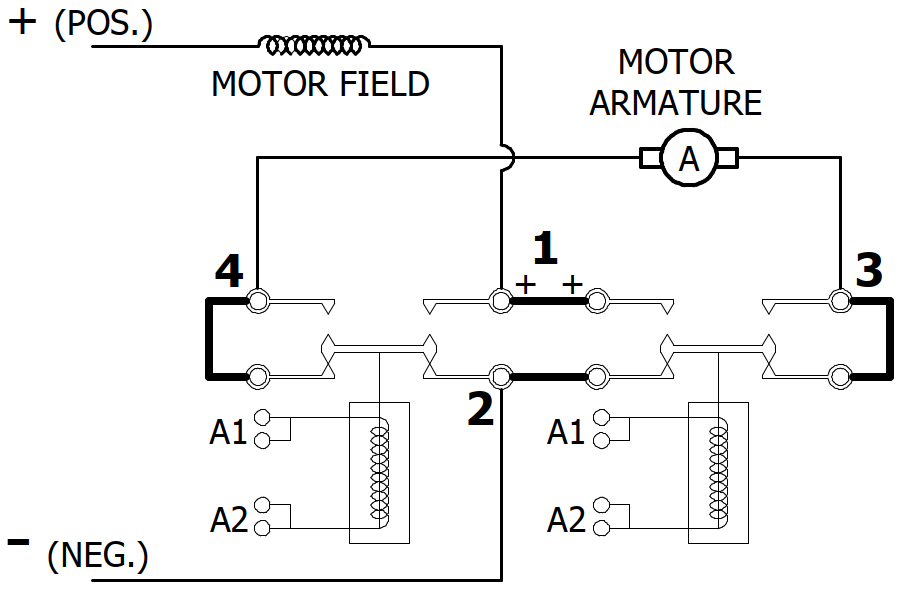

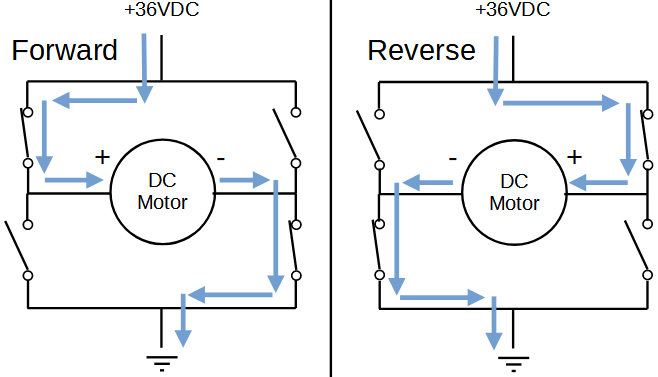

The forward/reverse contactors are N.O. DPDT switches that are paired together to switch polarity to the motor armature to control motor direction. They operate as an H-bridge as follows:

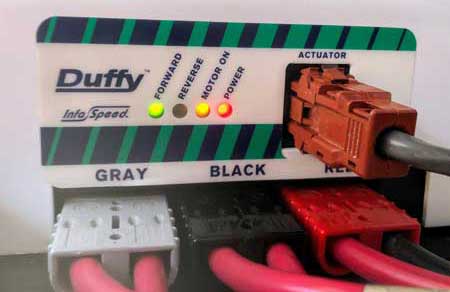

The physical implementation is as follows: